Watch Micro-Dramas on Mobile: The Ultimate Guide to Bite-Sized Entertainment

In today’s fast-paced world, finding time for entertainment can be challenging. That’s where micro-dramas come in—short, engaging stories perfect for watching on your mobile device during breaks, commutes, or whenever you have a few spare minutes.

Why Micro-Dramas Are Perfect for Mobile Viewing

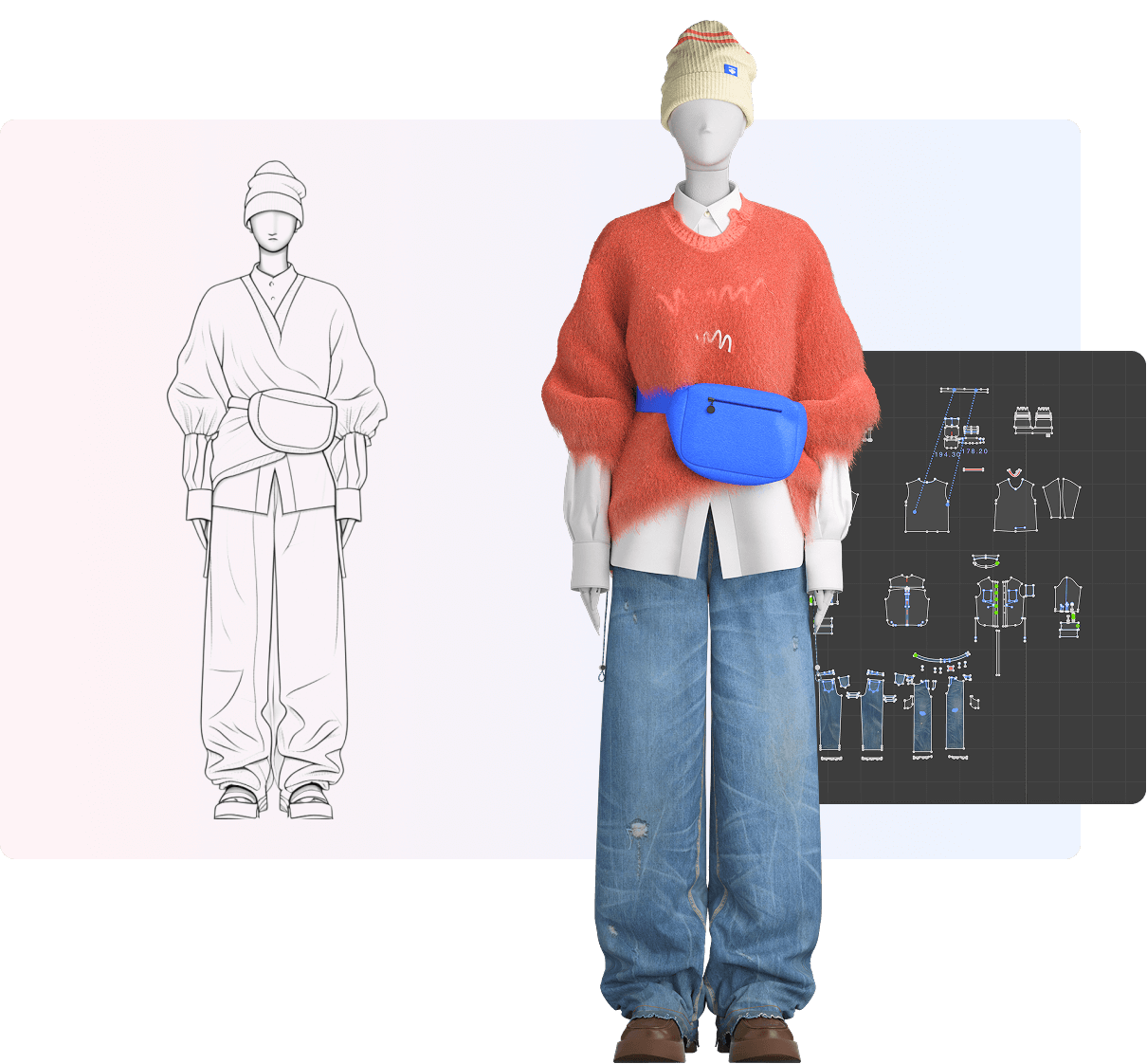

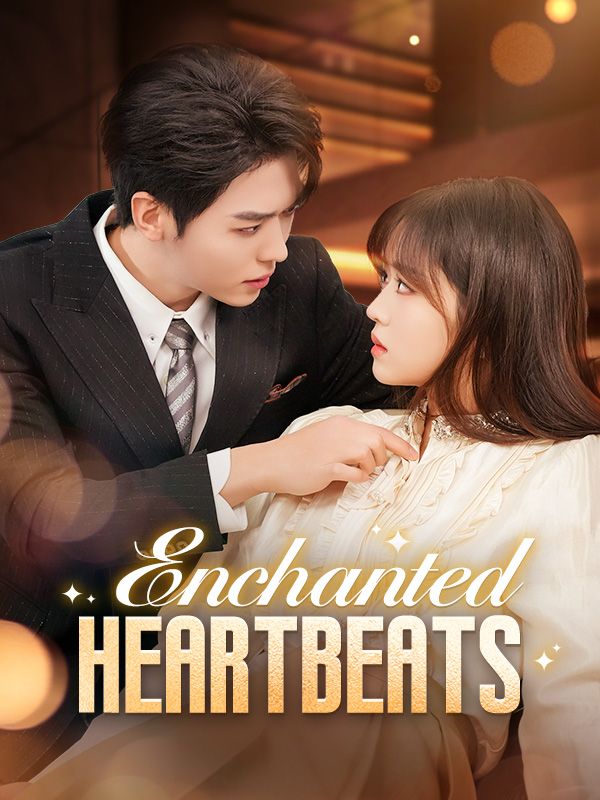

Micro-dramas, typically lasting between 1 to 10 minutes, are designed for quick consumption. Their compact format makes them ideal for mobile users who want instant gratification without long commitments. With vivid storytelling and high production quality, they deliver emotion and excitement in bite-sized chunks.

Top Platforms for Streaming Short Dramas

Numerous apps and websites specialize in micro-dramas, offering curated content across genres like romance, thriller, and comedy. Popular options include YouTube Shorts, TikTok, and dedicated drama apps. For an optimized experience, Watch Micro-Dramas on Mobile via platforms that prioritize mobile-friendly interfaces and offline downloads.

Benefits of Watching Micro-Dramas

These short episodes reduce screen time while maximizing engagement. They’re great for stress relief, creativity boosts, and discovering new storytellers. Plus, they often feature diverse voices and innovative narratives you won’t find in traditional media.

How to Get Started

Begin by exploring trending micro-dramas on social media or app stores. Create accounts on platforms that recommend content based on your preferences. Enable notifications for new releases to stay updated.

FAQs About Micro-Dramas

What are micro-dramas?

Micro-dramas are ultra-short video stories, usually episodic, designed for quick viewing on mobile devices.

Are they free to watch?

Many platforms offer free access with ads, while premium subscriptions provide ad-free and exclusive content.

Can I download episodes offline?

Yes, most apps allow downloads for offline enjoyment, perfect for travel or low-connectivity areas.

Join the Micro-Drama Revolution Today!

Don’t miss out on this growing trend—explore micro-dramas to transform your downtime into thrilling entertainment. Share your favorite finds with friends and start discussing episodes online!

Ready to dive in? Discover top-rated micro-dramas now and elevate your mobile viewing experience!